The NET effect of dispersants — a critical review of testing and modelling of surface oil dispersion

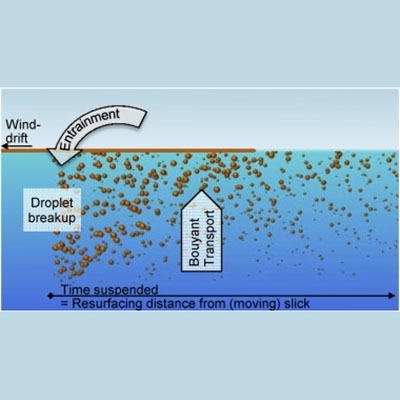

Application of chemical dispersants or mechanical dispersion on surface oil is a trade-off between surface effects (impact of floating oil) and sub-surface effects (impact of suspended oil). Making an informed decision regarding such response, requires insight in the induced change in fate and transport of the oil. We aim to identify how natural, chemical and mechanical dispersion could be quantified in oil spill models. For each step in the dispersion process, we review available experimental data in order to identify overall trends and propose an algorithm or calculation method. Additionally, the conditions for successful mechanical and chemical dispersion are defined. Two commonly identified key parameters in surface oil dispersion are: oil properties (viscosity and presence of dispersants) and mixing energy (often wind speed). Strikingly, these parameters play a different role in several of the dispersion sub-processes. This may explain difficulties in simply relating overall dispersion effectiveness to the individual parameters.